|

|

|

| |

Woven

Wire Partition-->How to Plan a Woven Wire

Partition |

|

|

|

|

|

|

|

|

|

|

| |

HOW TO PLAN STOCK SIZE

WIRE PARTITIONS |

|

| |

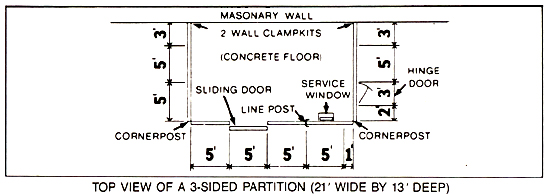

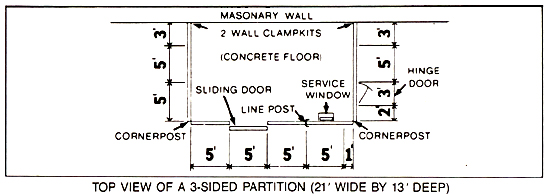

- Make a floor plan include measurements. Determining partition height,

7', 8', 10'

- Indicate doors, gates and service windows and their size and location. Show the direction of the slide gate or hinged door either left- or right-handed and swing in or out.

- Be sure to utilize as many 5 ft. wide panels as possible for most efficient

cost. Add one channel stiffener post for every 2 panels. (Stiffener posts are needed for each door and gate).

- If partition is to be installed between two walls, you may want to use the adjustable panel from stock instead of a special width often required. Wall clamp kit for each partition to wall

onnection. Use corner posts, or adjustable corner posts at all corners.

- Top capping in 10-foot section must needed in the construction. Calculate the total linear feet and round up to the nearest multiple of 10, then divide by 10 for the number of top capping sections. Example: Actual 75'5" linear feet: order 8 top capping sections (80 ft total).

|

|

| |

|

|

| |

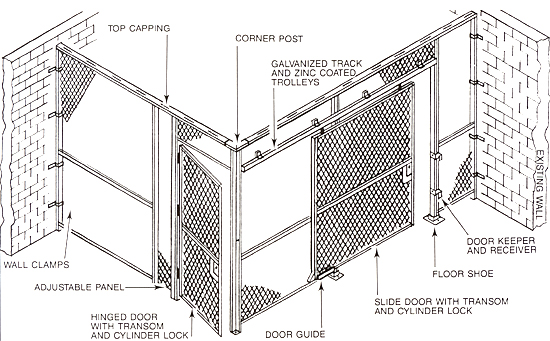

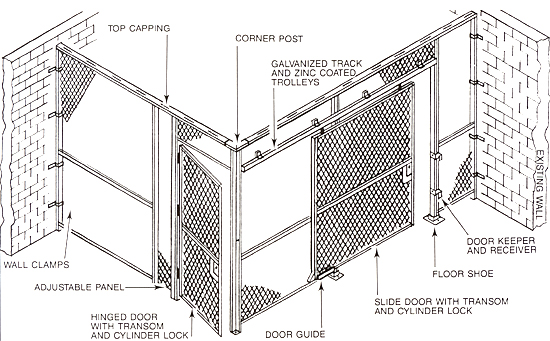

- At least 2 people required to assemble partition.

- If starting at an existing wall, start first panel from wall, if it is a free-standing room, start at a corner.

- Bolt panels together loosely. Do not secure floor sockets to the floor until fully assembled.

- install channel stiffener posts every 10-15 feet. Channel stiffener posts are needed for doors.

- After all panels and doors are assembled, attached top capping channel. Top capping channel should span panels and splices should be in the middle of a panel for maximum strength.

- Tighten panel bolts.

- Attach floor sockets using appropriate hardware.

|

|

|